Nano Ammeter for Industrial Use

The Nano Ammeter is a precision instrument designed for measuring extremely small currents, down to the nanoampere range, with applications in various industrial settings. The device also has the flexibility to function as a pico ammeter with minor modifications, showcasing its versatility. It is built with a focus on high accuracy and reliability, crucial for environments where even the slightest measurement errors can significantly impact outcomes.

Technical Features and Design Challenges

The design of the Nano Ammeter required meticulous attention to detail, particularly in handling extremely low currents. The analog section was shielded and insulated to minimize noise interference and ensure accuracy, even in harsh industrial environments. Key features include:

- High Sensitivity: Capable of detecting currents in the nanoampere range, with provisions for picoampere measurements.

- Noise Reduction: Advanced shielding and the use of high-quality materials reduce electromagnetic interference, ensuring accurate readings.

- Thermal Stability: Designed to operate reliably across a wide temperature range, from below freezing to above 50°C.

- Industrial-Grade Components: Utilizes components with low offset and drift, essential for maintaining precision over long periods.

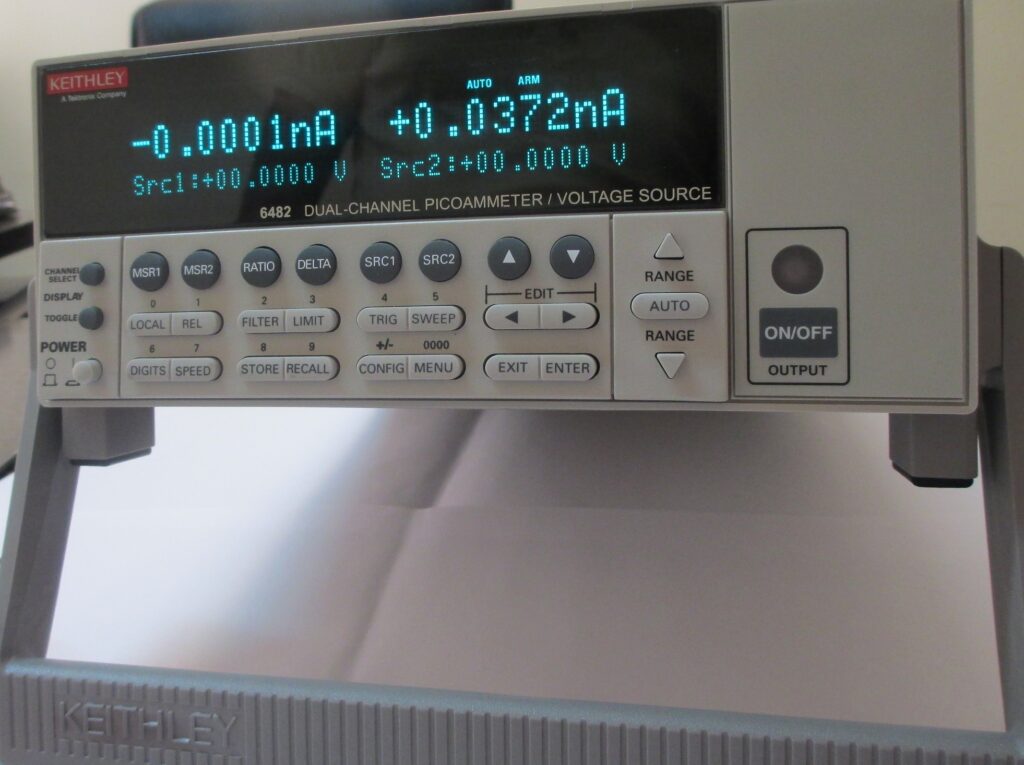

Calibration

To ensure the highest level of accuracy, the Nano Ammeter was meticulously calibrated using industry-standard equipment. Calibration was performed with a Keithley 6221 Series Source Meter, known for its precision current sourcing capabilities, and verified using a Keithley 6482 Picoammeter, which provides highly accurate current measurements. This calibration process ensures that the Nano Ammeter delivers reliable and consistent performance across its operating range.

Applications

The Nano Ammeter is suitable for use in sensitive industrial applications, including:

- Sensor Calibration: Ideal for calibrating sensors that operate at very low currents.

- Leakage Current Measurement: Useful in testing and quality control processes where detecting minute leakage currents is critical.

- Research and Development: Applicable in R&D settings where precise current measurements are necessary for developing new materials and technologies.

Environmental Considerations

The device is ruggedized for industrial use, featuring:

- EMI Shielding: Comprehensive shielding to protect against electromagnetic interference.

- Environmental Protection: Designed with special enclosures to protect against moisture and dust, ensuring durability and longevity.